I get this great opportunity ever quarter to use big machines I’ll never have room for in my own shop. For $ 150 a quarter, I can sign up for Woodworking II at Seattle Central. They have eight Saw Stops, a 20″ helix head planer, an 8″ helix head jointers and a big ass dust collection system. The beauty of it .. I don’t have to maintain a single one of them.

So off to school with my big pieces a maple for my workbench project. Class starts this week which is why I’m starting now. Originally, all I did was a rough break down the stock. Now I need start milling the pieces which is where the machines at school come in.

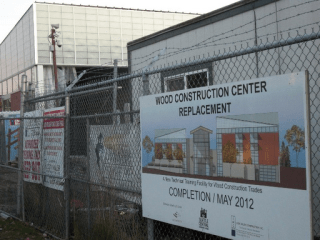

BTW, Seattle Central invested in $ 25 M (as in million) in a new Wood Construction Center building. It’ll be opening later this year. I’m sure it’ll be mostly for the day time classes, but hey, the evening crew is bound to get some benefits from it as well.